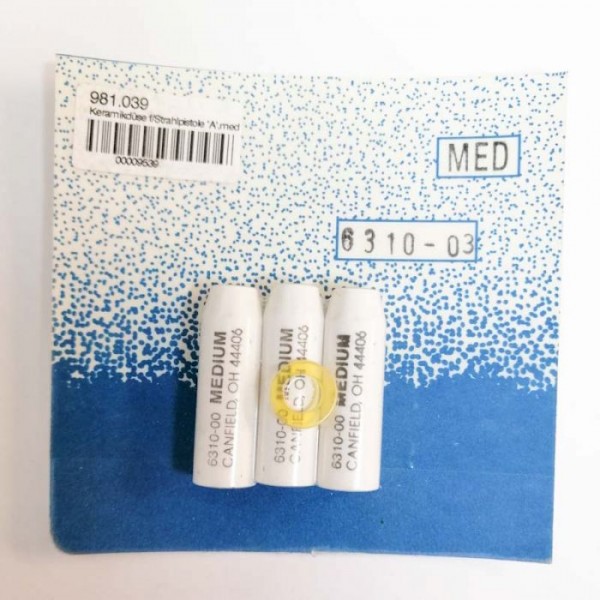

Glastar - Carbide Nozzle for Blast Gun A - Medium

9538

Glastar - Carbide Nozzle For Blast Gun A medium 6mm

To save wear on the gun power head, replace the air jet on ceramic nozzels with every 2-3 new nozzles. For carbide nozzles; change the air jet 3 times during the life of the nozzle.

Carbide nozzles last 30 times longer than ceramic nozzles when used in siphon blast guns.

Saves time when blasting: not having to stop and replace nozzles.

Carbide nozzles are ideal for non-stop blasting operation and very economical in the long run.

CA Sandblasting Nozzle constricts the high pressure stream of abrasive at the end of the hose and directs it at the project. The abrasive rushing through the nozzle enlarges the hole, and eventually, it must be replaced. The length of time a nozzle can be used depends on whether it is ceramic or tungsten carbide and how much air your compressor can produce.

|

Nozzle Size |

CFM / LPM at 40 PSI |

CFM / LPM at 60 PSI |

CFM / LPM at 80 PSI |

Compressor at 80 PSI |

|

1/16" / 1.6mm |

2 cfm / 57 lpm |

3 cfm / 85 lpm |

4 cfm /113 lpm |

2HP |

|

3/32" / 2.4mm |

5 cfm /142 lpm |

7 cfm /198 lpm |

9 cfm /255 lpm |

3-5HP |

|

1/8" / 3.2mm |

9 cfm /255 lpm |

13 cfm/368lpm |

17cfm/481 lpm |

5HP |

Air required for continuous blasting at a given nozzle aperture

As you see from the above chart, if you start with a 1.6mm nozzle blasting at 40 PSI (typical glass sand blasting pressure) by the time the aperture has worn to 2.4mm you would already be beyond the capacity of a 2 HP compressor and would have to replace the nozzle. So, the larger your compressor, the longer the useful life of a particular size nozzle.

9538 0.080000